福特卡车使用RFID跟踪工具

机会

福特汽车(Ford Motor)是全球汽车行业的领导者,总部位于密歇根州汽车横跨六大洲。公司在全球拥有约21.3万名员工和90家工厂公司的全资品牌包括福特、林肯、水星和沃尔沃。

2007年,福特对其卡车车主进行了调查,询问2009年的f系列卡车和e系列货车可能会增加哪些有用的功能。一个常见的要求是帮助承包商找到并跟踪他们的工具,以便在往返于工作地点时能得到最好的装备并提高生产效率。福特联系了总部位于马里兰州的工业电动工具领先制造商德沃特(DeWALT),分享了承包商如何应对维护工具库存这一挑战的见解。

福特开始评估技术,以解决其核心卡车客户“未满足”的需求。该公司研究了许多自动识别方法,包括条形码系统。他们意识到,由于需要用户手动扫描每个工具的条形码,这些方法过于耗费人力。福特随后将注意力转向RFID,并发现被动EPC第2代UHF RFID标签具有吸引力,因为其易于使用和低成本。这使得福特公司成为领先的RFID技术开发商ThingMagic,包括提供高性能和标签读取精度的嵌入式RFID阅读器模块。

解决方案

RFID是无线跟踪工具的理想技术,施工人员带着正确的工具和材料到达和离开。此外,RFID可以通过实时库存更新来防止设备和用品的丢失。如果承包商去工地时忘记了一件重要的工具,就会浪费宝贵的时间和生产力。一旦卡车能够帮助跟踪自己的物品,丢失工具和其他物品就更难了。

福特、DeWALT和ThingMagic合作设计坚固可靠的RFID标签,使承包商能够轻松地标记和识别特定的、工具、设备和其他资产。随后,两家公司整合了DeWALT RFID标签、ThingMagic RFID阅读器和天线,以及福特车载计算机系统上的工作解决方案和仪表板LCD显示器,创建了工具链接RFID应用程序。

然而,最初的原型遇到了障碍,因为金属,比如卡车车身,往往会使超高频信号发生偏移,使得被动超高频RFID标签有时难以读取。

利用其RFID技术,ThingMagic决定利用卡车的金属车身来补充RFID天线。由于车架变成了一个金属容器,信号在里面来回跳动,ThingMagic能够读取和解析信号,并提高了tis RFID天线和读取器的能力,能够准确读取卡车上的所有标签。

不同的气候,包括雨、雪、酷暑和冬季的严寒,以及工作现场的情况,加上泥浆、建筑垃圾、松散的石头和其他可能破坏解决方案的材料,构成了额外的挑战。通过加固RFID标签、读取器和天线,该团队克服了气候和环境障碍。通过设计,ThingMagic RFID阅读器已经支持-20°C到+60°C的工作温度范围,从而消除了极端温度的障碍。

福特Dewalt工具链接

Thingmagic与福特汽车公司(Ford Motor Company)和DeWalt密切合作,开发了一种基于RFID的创新解决方案,用于跟踪车辆上的工具。DeWalt™的Ford Work Solutions™tool link™使用超高频RFID技术来识别卡车中的物品。

它是如何工作的?

ThingMagic在设计系统的主要挑战是了解RFID标签的性能工具和开发创新的方法来提高阅读率,创建一个自定义M6e-based模块能够由一个汽车电池,和加固的生存和执行在日常环境中福特汽车服务他们的客户。

只需将所包含的RFID标签附加到要跟踪的任何工具或设备上。将工具放入卡车或货车中,使用工具链接系统进行扫描。系统标识每个标记,您可以输入项目的名称。一旦库存完成,系统可以跟踪标记的物品,无论它们何时在卡车上,并提供一个警报,如果他们失踪。只要在工具链接屏幕上轻轻一触,你的卡车就会确保你在上班前有你需要的工具。

有什么好处?

在你去工作之前检查工具链接,确保你有你需要的工具。在工作日结束时再检查一次,以确认工作场所使用的所有设备都已恢复正常。您可以将newitems添加到现有的目录中,甚至可以创建特定于工作的目录。下班后,使用工具链接跟踪用于露营、狩猎或其他爱好的物品。无论是跟踪压缩机还是滑车箱,工具链都是一项有用的技术。

结论

购买带有RFID功能的福特卡车和货车的承包商将DeWALT RFID标签放置在他们的工具或工具箱上,然后将每个标签的简短工具描述输入福特工作解决方案in-dash计算机。由一个保护性的坚硬的塑料外壳制成,如果标记一个特殊的工具外壳有问题,标签可以通过一个胶背或一个小孔和拉链连接。

当车辆启动或用户启动时,一对安装在耐腐蚀和耐冲击外壳中的神奇RFID天线会自动扫描带有RFID标签的物品。标签数据通过RFID阅读器传输,RFID阅读器将每个标签上的唯一编号与所附的工具相关联。这些信息会立即在触摸屏仪表盘计算机上显示和访问,帮助用户完成特定工作所需的工具的自动清单。工具链接还可以用来收集关于离开工作地点时卡车底座上有什么东西的信息,并将其与到达工作地点时车上有什么工具进行比较,以确保没有留下任何工具。此外,车主可以为特定的工作创建工具列表,详细说明在前往特定的工作地点之前需要在卡车里放些什么。

解决方案组件包括:

ThingMagic M6e读卡器模块和车载外壳

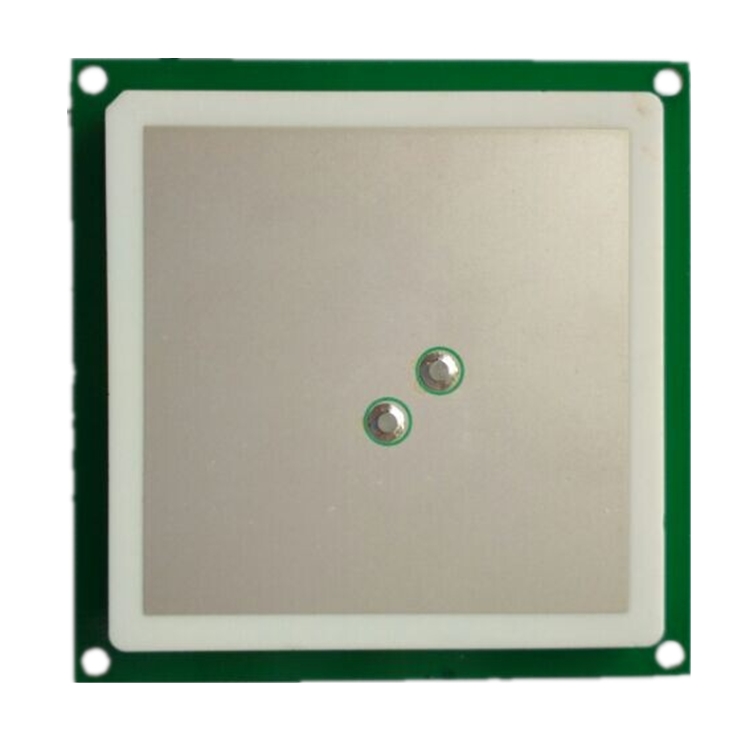

安装在耐腐蚀和抗冲击外壳中的RFID天线

耐用的超高频RFID DeWALT工具标签

福特工作解决方案™车载计算机系统和仪表板液晶显示器

最终用户的好处:

高价值的工具和材料管理

减少与设备丢失相关的成本

提高工人的生产力

提高工作效率和安全性

福特汽车公司工作解决方案产品和业务开发经理Bill Frykman说:“建筑公司和专业人士向福特卡车寻求坚固、可靠和技术先进的车辆。”“与嵌入式RFID技术行业专家ThingMagic和专业电动工具行业领导者DeWALT合作,我们开发了一套RFID系统,‘打造福特朗德’,提高了客户的生产率,为他们节省了成本。

可信的RFID部件

许多供应商可以提供各种各样的RFID产品可供选择,但与大多数数据收集制造商,JADAK拥有广泛的RFID产品组合,由工程师的资源和专业技术支持,帮助客户实现解决方案来满足他们的特定的需要和需求。

关于JADAK:

JADAK是诺万塔公司的一个业务部门,在机器视觉、RFID、条形码、打印以及为原始设备制造商提供的色光测量产品和服务方面处于市场领先地位。该公司设计并制造嵌入式检测和分析解决方案,帮助客户解决独特的检测、跟踪、扫描和记录方面的挑战。公司已通过iso9001和13485认证。

诺万塔是oem在医疗和先进工业技术市场值得信赖的技术合作伙伴,在光电子、视觉和精密运动技术方面拥有深厚的专业知识。

ThingMagic是JADAK的RFID产品和服务系列。

FORD TRUCKS USE RFID TO TRACK TOOLS

THE OPPORTUNITY

Ford Motor, a global automotive industry leader based in Michigan, manufactures or distributes automobiles across six continents. With about 213,000 employees and 90 plants worldwide, the company’s wholly owned brands include Ford, Lincoln, Mercury and Volvo.

Canvassing its truck owners in 2007, Ford asked what useful features might be added to its 2009 F-Series trucks and E-Series vans. One common request was to help contractors find and keep track of their tools, in order to be best equipped and more productive when traveling to and from job sites. Ford contacted Maryland-based DeWALT, a leading manufacturer of industrial power tools, to share insights into how contractors address this challenge of maintaining their tool inventories.

Ford began assessing technology to resolve this "unmet" need of its core truck customers. The company researched a number of auto-ID methods, including barcode systems, which they realized were too labor intensive as they required users to manually scan each tool’s barcode. Ford then turned its attention to RFID and found passive EPC Generation 2 UHF RFID tags attractive due to their ease-of-use and low cost. This led Ford to ThingMagic, a leading developer of RFID technology, including embedded RFID reader modules that offered high performance and tag reading accuracy.

THE SOLUTION

RFID is the ideal technology for wirelessly tracking tools and construction crews arrive at and depart with the right tools and materials. Additionally, RFID can be used to prevent the loss of equipment and supplies through real-time inventory updates. If a contractor goes to a job site and forgets an important tool, valuable time and productivity is lost. It's harder to lose tools and other items once the trucks can help keep track of their own contents.

Ford, DeWALT and ThingMagic collaborated to design rugged and reliable RFID labels that would allow contractors to easily tag and identify specific, tools, equipment, and other assets. The companies then integrated the DeWALT RFID tags, ThingMagic RFID readers and antennas, and the Ford Work Solutions™ on board computer system and dashboard LCD display to create the Tool Link RFID application.

Initial prototypes hit a road block, however, because metals, like truck bodies, tend to deflect UHF signals, making passive UHF RFID tags sometimes difficult to read.

Capitalizing on its RFID expertise, ThingMagic determined it could exploit the trucks’ metal bodies to complement the RFID antennas. Since the vehicle frame becomes a metal container in which the signals bounce around, ThingMagic was able to read and parse the signals and increase the ability of tis RFID antennas and readers to accurately read all tags onboard the truck.

Varying climates, including rain, snow, heat and the cold of winter, and on job site conditions, with mud, construction debris, loose stones and other materials that could potentially damage the solution, posed additional challenges. The team overcame climate and environmental obstacles by ruggedizing the RFID tags, readers, and antennas. By design, the ThingMagic RFID readers already supported an operating temperature range of -20°C to +60°C, thus removing the obstacle of extreme temperatures.

FORD TOOL LINK BY DEWALT

ThingMagic worked closely with Ford Motor Company and DeWALT to develop an innovative RFID-based solution to track tools on vehicles. Ford Work Solutions™ Tool Link™ from DeWALT™ uses UHF RFID technology to identify what is in a truck.

How it works?

ThingMagic’s primary challenges in designing the system were to understand the performance of RFID tags on tools and develop innovative methods to increase read rates, creating a custom M6e-based module capable of being powered by a vehicle battery, and ruggedized to survive and perform in the everyday environments where Ford vehicles serve their customers.

Simply attach the included RFID tags to any tools or equipment you want to track. Place the tools in the truck or van and use the Tool Link system to scan them. The system identifies each tag, and you can type in the name of the item. Once the inventory is complete, the system can track the items tagged whenever they are in the truck, and provide an alert if they are missing. With a simple touch on the Tool Link screen, your truck will make sure you have the tools you need before you leave for the job.

What’s the benefit?

Check Tool Link before you leave for a job to make sure you have the tools you need. Check it again at the end of the workday to confirm that all the gear used at the job site is back on board. You can add newitems to an existing inventory and even create job-specific inventories. Off the job, use Tool Link to track items used for camping, hunting or other hobbies. Whether it's tracking a compressor or a tackle box, Tool Link is a useful piece of technology.

CONCLUSION

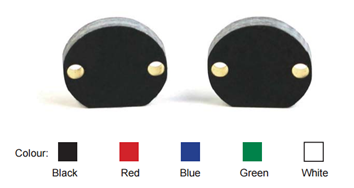

Contractors who purchase RFID-enabled Ford trucks and vans place the DeWALT RFID tags on their tools or tool cases, and then enter a brief tool description for each tag into the Ford Work Solutions in-dash computer. Made with a protective tough plastic housing, the tags are attached through an adhesive backing or through an eyelet and zip tied if tagging a particular tool casing is problematic.

When the vehicle is started or when the user initiates, a pair of ThingMagic RFID antennas, mounted in corrosion- and impact resistant housings, automatically scan for RFID-tagged items. Tag data is transmitted via the RFID readers which associate the unique number on each tag with the tool to which it is attached.This information is instantly displayed and accessible on the touch screen dashboard computer, helping users complete an automated inventory of tools needed for a specific job. Tool Link can also be used togather information about what is in the truck bed when leaving a job site, and compare that to what tools were on board when arriving at the site, making sure that no tools have been left behind. Furthermore, vehicle owners can create lists of tools for specific jobs, detailing what needs to be in the truck before heading to a particular job site.

The solution components included:

ThingMagic M6e reader module & in-vehicle housing

RFID antennas mounted in corrosion and impact resistant enclosures

Durable UHF RFID DeWALT tool tags

Ford Work Solutions ™ on-board computer system and dashboard LCD display

The End-User Benefits:

High value tool & material management

Reduced costs related to lost equipment

Improved worker productivity

Improved worksite efficiencies and safety

“Construction companies and professionals turn to Ford trucks for rugged, reliable and technicallyadvanced vehicles,” said Bill Frykman, Ford Work Solutions product and business development manager of Ford Motor Company. “Working with ThingMagic, the industry expert in embedded RFID technology, and DeWALT, the industry leader in professional power tools, we’ve developed an RFID system ‘Built Ford Tough’ that increases our customer’s productivity and saves them money.”

A TRUSTED RFID PARTNER

Many suppliers can offer a wide variety of RFID products to choose from but unlike most data collection manufacturers, JADAK has one of the broadest RFID product portfolios in the industry, backed by engineers with the resources and technical expertise to help customers implement solutions to meet their specific needs and requirements.

ABOUT JADAK:

JADAK, a business unit of Novanta, is a market leader in machine vision, RFID, barcode, printing, and color and light measurement products and services for original equipment manufacturers. The company designs and manufactures embedded detection and analysis solutions that help customers solve unique inspection, tracking, scanning and documenting challenges. The company is ISO 9001 and ISO 13485 registered.

Novanta is a trusted technology partner to OEMs in the medical and advanced industrial technology markets, with deep proprietary expertise in photonics, vision and precision motion technologies.

ThingMagic is JADAK’s RFID line of products and services.

ThingMagic与JADAK(杰达克)的RFID技术结合,将产生更为强大助力,推动RFID行业的发展。

深圳市铨顺宏科技有限公司作为美国JADAK旗下ThingMagic的中国区总代理商,为您提供ThingMagic的超高频RFID模块、超高频RFID读写器以及超高频RFID天线和标签。ThingMagic作为全球领先的RFID设备制造商,可以在保证稳定性和准确性的前提下,其核心产品具备750张标签每秒的读取速度,强大的多标签防碰撞算法,高速的信息读取与处理能力。深圳铨顺宏以专业的技术支持,用心服务于每位客户和用户,帮助客户将ThingMagic产品广泛应用于RFID服装零售智慧门店、RFID医疗智能化管理,RFID档案票据管理、RFID公检法物证管理,RFID银行款箱及票据管理、RFID电力电网和巡检管理、RFID航空行李管理、RFID物流自动化分拣,RFID精准农渔业智能化等多个领域。

咨询电话:400-0581-580!

同类文章排行

- 物联网护士站!RFID与传感技术如何提升病患管理智能化?

- 蓝牙亮灯标签与RFID手持机结合的RFID仓储解决方案

- RFID模具管理解决方案

- 铨顺宏超高频 RFID 智能工具管理

- 基于RFID技术在智慧工厂中的应用

- RFID医药供应链管理系统解决方案

- 超高频RFID技术在货物自动分拣系统中的应用

- 基于RFID技术的酒店布草洗涤管理系统应用

- 基于企业管理的RFID资产管理系统解决方案

- 基于RFID技术智慧珠宝门店管理系统应用

最新资讯文章

您的浏览历史